The trebuchet, in all its forms, was very much in the vogue in the reenactment and research community in the 1980s and 1990s. Several museums around the world have also built their own, with Middelaldercenteret in Nykøbing Falster in Denmark as one of the first modern examples of counterweight trebuchet. Despite the multitude of builds, very little has been published about the process. When it comes to the traction machines, the authors are only aware of Tarver’s influential article. From the historical perspective, Paul Chevedden, amongst others, brought focus to the traction-based version of the machine, which is more commonly considered as an introductory note of the more awe-inspiring counterweight. At the Tower of London, a traction trebuchet clearly modelled on counterweight machines uses a pulling crew of about 4 people, throwing across the grass along the length of the outer walls.

The first functional traction trebuchet that our group built was in 2008, by a team consisting of a Computer Science Professor, students studying game development, and a lumberjack. The main structure was constructed from trees that were cut down on-site on the Saturday morning of the construction weekend. The construction was on the grounds of the University College, which allowed us to select the trees to cut down. The remaining materials, including nails, rope, and a leather hide had been purchased before construction began. The subsequent builds were mainly at the Medieval Festival held at Hamar each June, and in 2017 the Middelaldercenteret in Nykøbing Falster was kind enough to allow us to come and use their reconstructed hand tools to build a version entirely with period tools, materials, and construction. The wood for the builds has come from trees chopped down either on site or nearby, with the owner’s approval. We have used a variety of trees, such as pine, birch and hazel. Other than the removal of branches and twigs, we have kept the logs in their original format, neither making planks nor shaving off more of the bark than necessary.

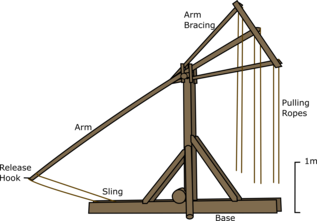

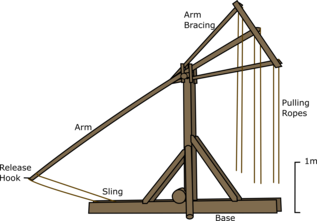

The largest machine to date was 3.5m at the axle with a 6.5m throwing arm, and the smallest was 1.8m at the axle with a 3m arm. The majority of machines have been in the 2m-2.5m range at the axle. Our crew generally consisted of six pullers and one sling holder. The pulling crew has usually had the two strongest (and often tallest) people in the middle position. They have also been responsible for using their ropes to slow the arm down once it reaches the end of its curve. Instructions have been simple, merely to keep the rope taut and then pull straight down when the sling holder calls for it. The position of sling holder requires focus and slightly more training that the pullers, but nothing that takes more than a few throws to get used to. Pulling teams consisting of two adults and four children easily throw as far as a team of four adults. Our projectiles have been whatever rocks we can find in the surrounding area. We try to keep them at an even size and weight, but there are natural variations. Despite this, these machines consistently throw rocks in the 2-4kg size about 80m, with a maximum of 120m with a light rock and coordinated team.

The largest machine to date was 3.5m at the axle with a 6.5m throwing arm, and the smallest was 1.8m at the axle with a 3m arm. The majority of machines have been in the 2m-2.5m range at the axle. Our crew generally consisted of six pullers and one sling holder. The pulling crew has usually had the two strongest (and often tallest) people in the middle position. They have also been responsible for using their ropes to slow the arm down once it reaches the end of its curve. Instructions have been simple, merely to keep the rope taut and then pull straight down when the sling holder calls for it. The position of sling holder requires focus and slightly more training that the pullers, but nothing that takes more than a few throws to get used to. Pulling teams consisting of two adults and four children easily throw as far as a team of four adults. Our projectiles have been whatever rocks we can find in the surrounding area. We try to keep them at an even size and weight, but there are natural variations. Despite this, these machines consistently throw rocks in the 2-4kg size about 80m, with a maximum of 120m with a light rock and coordinated team.

The largest machine to date was 3.5m at the axle with a 6.5m throwing arm, and the smallest was 1.8m at the axle with a 3m arm. The majority of machines have been in the 2m-2.5m range at the axle. Our crew generally consisted of six pullers and one sling holder. The pulling crew has usually had the two strongest (and often tallest) people in the middle position. They have also been responsible for using their ropes to slow the arm down once it reaches the end of its curve. Instructions have been simple, merely to keep the rope taut and then pull straight down when the sling holder calls for it. The position of sling holder requires focus and slightly more training that the pullers, but nothing that takes more than a few throws to get used to. Pulling teams consisting of two adults and four children easily throw as far as a team of four adults. Our projectiles have been whatever rocks we can find in the surrounding area. We try to keep them at an even size and weight, but there are natural variations. Despite this, these machines consistently throw rocks in the 2-4kg size about 80m, with a maximum of 120m with a light rock and coordinated team.